How to Choose an Electronic Waste Recycling Company for Local and Nationwide Needs

Think of an electronic waste recycling company as more of a specialized security and logistics partner than a simple junk hauler. These aren't the folks you call for a garage cleanout; they are critical service providers who safely bridge the gap between your old equipment and the complex world of data security, environmental compliance, and legal liability, whether you're a local business or a national corporation.

What an Electronic Waste Recycling Company Actually Does

Many businesses make the mistake of seeing e-waste disposal as just another line item on a cleanup checklist. That's a risky view. In reality, it's a minefield of risk management, data security protocols, and environmental stewardship. A professional partner manages the entire end-of-life journey for your retired assets, transforming a huge potential liability into a secure, documented, and closed-loop process.

A good way to picture it is like a high-security courier service, but instead of handling sensitive documents, they’re moving servers, lab instruments, and entire racks of computers. That’s their job in a nutshell: securely collecting, transporting, processing, and certifying the final disposition of your technology assets for clients across the country and in local areas like Atlanta.

Core Functions and Client Needs

A certified e-waste partner handles several critical jobs that most organizations are not equipped to manage internally. Their services solve major headaches for everyone from national hospital networks and universities to local Atlanta-area businesses.

Here are the key problems they solve on a daily basis:

- Preventing Data Breaches: They use proven methods like DoD 5220.22-M wiping and physical hard drive shredding to make absolutely sure that sensitive information on old devices is gone for good.

- Ensuring Regulatory Compliance: They provide the official paperwork—like Certificates of Data Destruction—that auditors and regulators need to see to prove you've complied with laws like HIPAA.

- Managing Complex Logistics: For big jobs like a full lab decommissioning, they handle the on-site de-installation, packing, and transportation. This takes a massive logistical burden off your team's shoulders, whether it's at one site or multiple locations nationwide.

At its core, a professional e-waste recycling company turns the challenge of asset retirement into an opportunity. They help you protect your brand, sidestep crippling fines, and contribute to a circular economy by recovering valuable materials from your old gear.

The scale of the global e-waste problem really underscores why these services are so vital. In 2022, the world generated a mind-boggling 62 million tonnes of electronic waste, but a dismal 22.3% of it was properly collected and recycled. This leaves billions of dollars in recoverable resources like gold and silver sitting in landfills—not to mention countless hard drives full of sensitive data just waiting to be found.

By managing the entire process from the moment a truck arrives at your facility to the final material recovery report, these companies provide true peace of mind. For a closer look at the nuts and bolts, you can check out our guide on what electronic waste recycling involves. They ensure every single piece of equipment is handled securely and responsibly, from start to finish.

Deconstructing Key Services: Logistics and Data Security

Choosing a partner for your electronic waste goes way beyond just finding someone to haul it away. A truly professional electronic waste recycling company builds its services on two critical pillars: airtight logistics and ironclad data security.

Think of it this way: logistics is the secure physical journey of your equipment from point A to point B, while data security is about permanently destroying the digital ghosts left inside. A failure in either area can spell disaster, leading to anything from stolen assets to a full-blown, public data breach. These two functions have to work hand-in-hand to protect your organization.

From Your Doorstep to Secure Transport

The logistics process starts long before a truck ever shows up at your facility. A top-tier provider coordinates the entire on-site de-installation and removal, which is absolutely essential for complex projects like a complete lab decommission or a national data center shutdown.

Imagine a hospital wing getting a major renovation. The vendor’s team would arrive to systematically disconnect, catalog, and pack everything—from sensitive diagnostic machines and centrifuges to server racks and hundreds of desktop computers. This isn't a simple moving job; it's a meticulously planned operation.

Key steps in the logistics process include:

- On-site Asset Inventory: Cataloging every single piece of equipment by serial number before it leaves your facility.

- Professional De-installation: Safely disconnecting all hardware, from heavy-duty servers to delicate lab instruments.

- Secure Packing and Transport: Using their own secure vehicles—never third-party shippers—to maintain a clear chain of custody.

This managed approach ensures nothing gets lost along the way and gives you a clear, auditable trail from your location straight to their secure processing facility.

The concept of "chain of custody" is absolutely vital. It's an unbroken, documented record of who has control of your assets at every single moment. This is your first line of defense against equipment theft and unauthorized access.

The Two-Pronged Approach to Data Destruction

Once your assets arrive safely at the secure facility, the focus shifts entirely to destroying the data they hold. Just relying on one method isn't enough for complete security. A truly professional electronic waste recycling company uses a dual strategy: data sanitization and physical destruction.

Data sanitization uses specialized software to completely overwrite the data on a hard drive, making it impossible to recover. The gold standard for this is the DoD 5220.22-M method.

To get a better picture of how this works, think of a sensitive document:

- Deleting a file is like tossing the document into a wastebasket. Anyone can just pull it out and read it.

- Formatting a drive is like shredding the document into strips. A determined person could still tape it back together.

- DoD 5220.22-M sanitization is like shredding the document, burning the strips to ash, and then scattering the ashes in the wind. That information is gone for good.

But what about hard drives that are damaged, failed, or just too old to run the software? That’s where the second prong—physical destruction—comes in. This involves feeding the hard drives and other media into industrial-grade shredders that grind them into small, unrecognizable pieces of metal and plastic. This is the ultimate guarantee that no data can ever be retrieved.

By combining both sanitization and shredding, a recycler provides a comprehensive security solution that meets strict compliance standards like HIPAA. To see how these methods protect your organization, you can learn more about secure data destruction and why it's so important.

Navigating Critical Compliance and Certifications

Picking an electronic waste recycling company without checking their certifications is like hiring a security guard without a background check—you're opening your organization up to enormous risk. Compliance isn’t just some environmental checkbox; it's your primary shield against crippling fines, data breach lawsuits, and the kind of reputational damage that takes years to fix.

The right certifications are proof that a vendor operates under strict, independently audited standards for security, safety, and transparency. They tell you that a partner has actually invested in the systems, training, and infrastructure needed to handle your sensitive assets the right way. For any organization, but especially those in healthcare, finance, or government, this documented proof is non-negotiable.

The Gold Standard Certifications to Look For

When you're vetting a potential partner, a few key acronyms should be at the very top of your checklist. These aren't just fancy badges; they represent tough operational standards that separate legitimate, professional recyclers from the risky, uncertified operators. A reputable company will be proud to show you these and provide documentation on request.

Here are the most critical certifications to demand:

-

R2 (Responsible Recycling): This is the leading global standard, and it covers the entire lifecycle of electronics. An R2-certified company must follow strict rules on data security, environmental protection, and worker health and safety. It also requires a secure, auditable downstream chain, so you know for a fact your materials aren't being illegally exported or dumped in a landfill.

-

RIOS (Recycling Industry Operating Standards): Think of RIOS as a comprehensive management system that brings quality, environmental, and health and safety requirements under one umbrella. It’s often paired with R2, creating a powerful combination that shows a deep commitment to operational excellence and risk management.

-

ISO 14001: This international standard is all about having an effective environmental management system (EMS). It proves a company is actively working to minimize its environmental footprint, comply with regulations, and constantly improve its green practices.

These certifications give you a framework that guarantees a baseline of professionalism and care, so you can have real confidence in your choice.

Why Certifications Matter in the Real World

Let's get past the acronyms and talk about how this actually affects your day-to-day. Imagine you're the risk manager for a hospital in Atlanta. The stakes are incredibly high. A discarded patient monitoring device or an old server could easily still contain protected health information (PHI), making HIPAA compliance your absolute top priority.

Choosing a partner without proven, HIPAA-compliant data destruction processes is a direct violation of federal law. A certified electronic waste recycling company provides a Certificate of Data Destruction, a legal document that serves as your auditable proof that all data was sanitized according to government standards.

Now, think about a national corporation with offices all over the country. They need a partner who can provide a consistent, auditable trail for every single retired asset. An R2-certified recycler guarantees this downstream visibility. They can track your materials from their facility all the way to the final smelter or refiner, ensuring every component is handled responsibly.

This prevents the nightmare scenario where your company-branded equipment is discovered in an overseas landfill, sparking a public relations disaster. For a deeper dive into managing old equipment, our article about IT equipment recycling provides valuable insights.

Ultimately, these certifications are your assurance that an electronic waste recycling company is truly equipped to protect you from the serious financial and legal fallout of improper disposal. They are the absolute minimum requirement for any vendor you consider trusting with your retired assets and the sensitive data they hold.

The E-Waste Journey: From Your Facility to Final Recovery

What really happens to your retired assets after they leave your control? For many organizations, it’s a total black box. A trustworthy electronic waste recycling company pulls back the curtain, giving you a transparent, secure, and fully documented path from your loading dock to final material recovery.

Let's walk through the typical workflow for a common scenario, like a multi-site office IT refresh involving hundreds of computers, monitors, and servers. Seeing these steps in action helps you appreciate the meticulous planning and security that goes into it.

Step 1: Secure On-Site Pickup and Transport

The journey starts right at your location. A professional team shows up with their own secure, company-owned vehicles—a critical detail that establishes an immediate, unbroken chain of custody. Before anything is loaded, they catalog every single asset by serial number, creating a complete inventory from the get-go.

This isn't just a simple pickup; it’s a coordinated logistical operation designed to minimize any disruption to your business while maximizing security.

Step 2: Arrival and Auditing at a Secure Facility

Once the truck arrives at the recycler's facility, the assets are moved directly into a secure, access-controlled area. Here, the intake team performs a detailed audit, reconciling the physical inventory against the list created back at your site. This double-verification step confirms that every last piece of equipment has arrived safely.

Each item—from a single server hard drive to a pallet of laptops—is officially logged into their asset management system. This creates a digital paper trail that will follow the asset through every single stage of the process.

The moment your equipment crosses the threshold of a certified facility, it enters a highly controlled environment. Every touchpoint is tracked, logged, and verified to maintain the integrity of the chain of custody and prepare for secure data destruction.

Step 3: Data Destruction and Media Sanitization

This is arguably the most critical phase of the entire process. All data-bearing devices are immediately segregated for sanitization. Hard drives and solid-state drives are wiped clean using DoD 5220.22-M 3-pass software, which renders the data completely unrecoverable. For any drives that fail the wiping process or are too damaged to be read, it's on to the next step: physical destruction.

These failed or obsolete devices are fed into industrial shredders that grind them into small, unrecognizable pieces of metal and plastic. This dual approach of sanitization and shredding provides an ironclad guarantee that your sensitive information is gone for good. Navigating the complexities of asset retirement can be challenging, but understanding the options for secure IT asset disposal can provide clarity and confidence.

Step 4: Manual Dismantling and Sorting

With all data securely destroyed, the equipment moves to the dismantling area. Here, trained technicians manually de-manufacture each device, breaking it down into its core components. This hands-on process is essential for maximizing resource recovery.

Technicians carefully separate materials into clean commodity streams:

- Plastics from casings and keyboards

- Metals like steel and aluminum from chassis

- Circuit boards rich in precious metals

- Glass from monitor screens

- Cabling containing copper

Step 5: Transfer to Downstream Partners

The sorted materials are then bundled and prepared for shipment to specialized, vetted downstream partners. No single facility can process every material type on its own. A certified recycler maintains a network of audited partners who are experts in refining specific commodities. Circuit boards go to a smelter to recover gold and copper, while plastics are sent to a processor to be turned into pellets for new manufacturing.

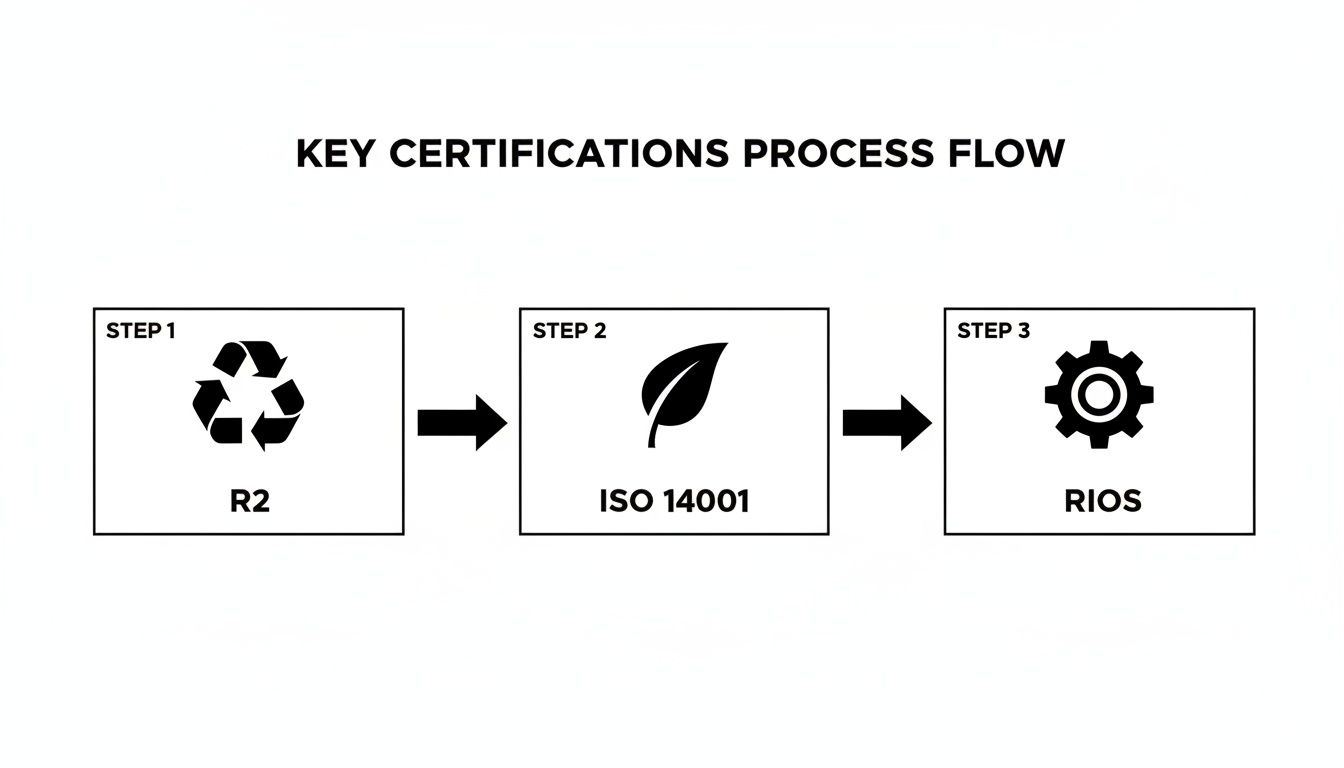

This visual below highlights how key certifications like R2, ISO 14001, and RIOS govern this entire process, ensuring every step is handled responsibly.

This flow isn't just a suggestion; it shows that these certifications are interconnected systems that demand environmental safety, quality management, and responsible recycling throughout the entire chain.

Step 6: Issuance of Final Certificates

The journey concludes when the official documentation lands in your inbox. You'll receive a Certificate of Data Destruction and a Certificate of Recycling. These documents are your legal proof that your assets were managed in full compliance with data privacy laws and environmental regulations, officially closing the loop on your asset disposition project.

Understanding the Costs and Real Value of E-Waste Recycling

When it comes to disposing of old technology, the first question on everyone's mind is usually "What's this going to cost me?" But that's not really the right question to ask. A better way to frame it is to focus on the immense value and risk mitigation you get from partnering with a professional. The truth is, the cost of doing this wrong is always, always higher than the investment in doing it right.

Pricing for e-waste services isn't a simple, flat-rate deal; it’s shaped by a few key variables. The type of equipment you have and how much of it there is are the biggest factors. Newer assets with valuable components like precious metals or reusable parts might actually generate a return, offsetting or even covering the recycling costs. On the flip side, older items or those with hazardous materials, like old CRT monitors, will likely have a disposal fee.

Factors That Influence Your Final Cost

Logistics and data security are the other big pieces of the puzzle. A straightforward pallet pickup from a loading dock in Atlanta is a much different project than a complex, multi-state lab decommissioning that needs a full team of technicians for on-site de-installation. The more hands-on work required, the more it will influence the final quote.

To help you get a clearer picture, we've broken down the common variables that determine the cost of a professional e-waste disposal project.

Key Factors That Influence E-Waste Recycling Costs

| Cost Factor | What It Means for Your Project | Typical Impact on Price |

|---|---|---|

| Equipment Type | Items with high commodity value (servers, circuit boards) can reduce costs. Those requiring special handling (lab gear with biohazards) may increase them. | High Value = Lower Cost Low Value/Hazardous = Higher Cost |

| Project Volume & Density | Larger volumes almost always lead to lower per-unit costs. One full truckload is far more efficient than several small pickups. | High Volume = Lower Per-Unit Cost Low Volume = Higher Per-Unit Cost |

| Logistical Complexity | Projects needing on-site labor, stair carries, or nationwide coordination will have higher associated costs. | Simple Logistics = Lower Cost Complex Logistics = Higher Cost |

| Data Destruction Method | Secure data wiping is often standard, but if you need on-site hard drive shredding or detailed inventory reporting, that will add to the price. | Standard Wiping = Included/Low Cost On-Site Shredding = Higher Cost |

Understanding these factors can help you better anticipate your project's budget. Some vendors even streamline logistics by offering services like electronic recycling free pick-up options for qualifying projects, which can significantly simplify the process.

Shifting Focus From Cost to Strategic Value

The real conversation shouldn't be about the invoice from your recycler. It should be about the catastrophic costs you're actively avoiding. Improperly disposing of your old equipment opens your organization up to some truly staggering financial and reputational damage.

A single data breach can cost a company millions in regulatory fines, legal fees, and customer notification expenses—not to mention the irreversible harm to your brand's reputation. Partnering with a certified electronic waste recycling company is a direct investment in risk management.

The global electronic waste recycling market, valued at USD 70.1 billion in 2024, is projected to soar to USD 251.9 billion by 2034. This explosive growth is driven by the sheer volume of e-waste and tightening regulations like the EU's updated WEEE Directive. Innovations in recovering valuable materials like gold and copper are turning old electronics into a massive resource. You can find more details on this trillion-dollar resource potential on gminsights.com.

For both national corporations and Atlanta-area hospitals and universities, this boom means better access to certified, cost-effective programs that can turn old liabilities into recoverable assets while ensuring data is securely destroyed. Choosing a compliant partner aligns your organization with this global movement, protecting you from rising compliance costs and supporting a circular economy.

How to Vet an E-Waste Partner: Your Checklist

Picking the right company to handle your old equipment is a big deal. It's a decision that hits your security, your legal compliance, and even your company's reputation. You need a solid game plan to make the right call. This checklist is your playbook, arming you with the critical questions to ask any potential e-waste recycler, whether they're a local Atlanta provider or a national firm.

Think of this like a high-stakes job interview. You wouldn't hire a key employee without some tough questions, right? Apply that same level of scrutiny here. This is how you tell the certified pros from the risky operators.

Questions About Security and Data Destruction

When it comes to your data, "good enough" won't cut it. Vague promises are a massive red flag. Your mission here is to get concrete, specific answers about how a vendor will protect your most sensitive information from the second it leaves your control.

- "Can you walk me through your entire data sanitization process, step-by-step?" A real professional will immediately bring up DoD 5220.22-M 3-pass sanitization for drives that still work and physical shredding for anything that's failed. Have them explain how they handle both scenarios.

- "What proof of data destruction will I get?" There's only one right answer here: a formal, serialized Certificate of Data Destruction. This document is your legal proof that you did your due diligence and is absolutely essential for any audit trail.

- "How secure is your facility?" Get specifics. Ask about their access controls, cameras, and whether they run background checks on employees. Their facility should be a fortress built to protect their clients' assets.

If a potential partner gets squirrely or can't give you clear, documented answers to these questions, walk away. Fuzzy promises about security usually mean they have inadequate processes—or none at all—and that puts your organization at serious risk.

Questions About Compliance and Certifications

Certifications aren't just fancy logos; they are your guarantee that a company is held to strict standards verified by a third party. They're the baseline for proving a vendor is serious about doing things legally and ethically.

- "Are you R2, RIOS, or ISO 14001 certified?" A simple "yes" is a good start, but don't stop there. Ask for their certification numbers or a copy of the certificate. Any legitimate electronic waste recycling company will be happy to show you their credentials.

- "How do you ensure your downstream partners are compliant?" This is a big one. An R2-certified recycler is required to audit everyone they work with down the line. Ask them about their vetting process to make sure your equipment doesn't end up illegally exported or dumped in a landfill.

- "Can you help us meet specific regulations like HIPAA?" If you're in healthcare, finance, or another regulated field, your vendor absolutely must understand your world. They need to have proven, documented processes in place to meet those specific compliance needs.

Questions About Logistics and Operations

How your assets are physically handled is just as important as how the data is destroyed. Shoddy logistics can lead to lost equipment, blown project timelines, and unexpected costs.

Here are the key things to drill down on:

- Do you use your own fleet of trucks and drivers? A company that uses its own vehicles and background-checked employees maintains a secure chain of custody. Relying on random third-party freight companies opens up a huge security gap.

- What's your service area, both locally and nationally? For businesses in the Atlanta area, confirm they can handle your specific location. If you have offices in other states, find out how they provide consistent service everywhere.

- What is your typical turnaround time from pickup to me getting the final certificates? This helps you manage your own project timelines and ensures you're not left waiting months for the paperwork you need to close the books.

By asking these direct questions, you take control of the conversation. You're looking for a partner who gives you transparent, confident, and documented answers. That's the hallmark of a true professional you can trust.

Common Questions About E-Waste Recycling

Even when you have a good handle on the process, some practical questions always come up before you sign on with an e-waste partner. Getting straight answers to these common concerns is the key to moving forward with confidence and making sure your project is smooth and secure from start to finish.

We've pulled together the most common questions we hear to give you some clarity.

What Types of Equipment Can Be Recycled?

A serious e-waste company should be able to take almost anything you can throw at them. Of course, this includes the usual IT hardware like servers, computers, networking gear, and laptops. But a truly capable partner also knows how to handle the specialized equipment from labs, hospitals, and manufacturing floors—think centrifuges, diagnostic machines, and industrial controls.

The goal is to find a provider who can be your one-stop shop. This is especially critical for something like a full facility decommission, where you don’t have time to juggle multiple vendors. It simplifies your logistics and ensures nothing gets left behind.

How Is Data Destruction Verified?

Proof that your data is gone for good comes from a mix of documented processes and official paperwork. Any recycler worth their salt must provide, at the very minimum, DoD 5220.22-M 3-pass data sanitization for any functional hard drive. For drives that are fried or just too old to wipe, physical shredding is the only way to go.

The most important piece of the puzzle is the formal Certificate of Data Destruction you receive after the job is done. This document is your official, auditable proof that you’ve met compliance standards. It's absolutely essential for regulations like HIPAA and protects your organization from any future liability.

This certificate is your guarantee that all your sensitive information was permanently destroyed according to strict industry standards.

Should I Choose a Local or National Company?

Deciding between a local or national provider really boils down to your company’s footprint and needs. A local company, like those serving the Atlanta metro area, can usually offer more flexibility, faster response times, and better pricing on transportation for regional projects. They're a perfect fit for single-site cleanouts or lab decommissions.

On the other hand, a national provider brings a standardized process and a single point of contact, which is a huge advantage for organizations with facilities all over the country. This ensures you get consistent service, pricing, and compliance reporting no matter where your sites are located. Many leading companies offer both local expertise and nationwide coverage to serve diverse client needs.

What Happens to the Materials After Processing?

Once all the data has been securely wiped or shredded and the equipment has been taken apart by hand, the components are sorted into clean material streams. We're talking about piles of different metals, plastics, and circuit boards.

These sorted commodities are then securely shipped to a trusted network of certified downstream partners. These are specialized facilities that are experts at refining these materials back into their raw forms. It's a closed-loop process that puts valuable resources back into the manufacturing supply chain, manages hazardous materials safely, and keeps virtually everything out of a landfill.

When your Atlanta-area hospital, lab, or business needs a partner you can trust for secure and compliant e-waste disposal, turn to Scientific Equipment Disposal. We make the whole process simple, from on-site de-installation to certified data destruction, providing both local service and nationwide logistics. Find out how we can help by visiting us at https://www.scientificequipmentdisposal.com.