Your Guide to a Compliant Medical Equipment Recycling Program

So, you've got a room full of outdated medical or lab equipment. What now? A formal medical equipment recycling program is your answer. It's more than just a disposal plan; it’s a strategic approach to responsibly managing those assets. Think of it as a playbook that ensures you’re compliant with data security laws like HIPAA, meeting all environmental regulations, and even getting some value back from that retired equipment. A solid, structured program helps hospitals and labs dodge major risks and keep costs in check, whether you're a single facility or a nationwide organization.

Why a Formal Recycling Program Is Non-Negotiable

Let's be clear: "we'll get to it eventually" is not a strategy for asset retirement. Ad-hoc, informal approaches are a recipe for trouble, creating massive blind spots that can lead to compliance violations, data breaches, and costs that appear out of nowhere. Whether you’re a facility manager in Atlanta trying to clear out old centrifuges or an IT director in Austin decommissioning servers, a formal program is absolutely essential. A nationwide medical equipment recycling program offers consistency for organizations with multiple locations.

This isn't just about bureaucracy. There are powerful financial, environmental, and compliance reasons driving this shift. A well-designed program doesn't just get rid of old equipment; it transforms a potential liability into a genuine sustainability asset.

Before we dive into the step-by-step process, let's look at the core pillars that make a program successful. These are the foundational elements we’ll be building upon.

Core Components of a Successful Recycling Program

| Pillar | Key Objective | Primary Benefit |

|---|---|---|

| Policy & Scope | Establish clear rules and define what equipment is covered. | Ensures consistency and eliminates confusion. |

| Data Security | Guarantee all sensitive data is properly destroyed. | Prevents data breaches and ensures HIPAA compliance. |

| Regulatory Compliance | Adhere to all federal, state, and local environmental laws. | Mitigates legal risks and avoids costly fines. |

| Vendor Management | Select certified and reputable recycling partners. | Provides peace of mind and a documented chain of custody. |

| Logistics & Tracking | Create a seamless process for de-installation and documentation. | Maintains control over assets from start to finish. |

| Cost & Revenue | Identify opportunities for value recovery and manage program expenses. | Turns a cost center into a potential revenue stream. |

Each of these pillars works together to create a system that is secure, compliant, and efficient. Now, let’s unpack why this is so critical.

Mitigating Critical Risks and Ensuring Compliance

The number one reason to formalize your program is risk. It’s that simple. Old diagnostic machines, patient monitors, and servers are often packed with Protected Health Information (PHI), which puts them squarely under the watch of HIPAA. One mistake in disposal can lead to crippling penalties and a public relations nightmare.

And it’s not just about data. The EPA has strict rules for handling electronics that contain hazardous materials. A formal program gives you a clear, documented process for managing these items correctly. You get an auditable trail that proves you did your due diligence, which is exactly what facility managers, IT directors, and compliance officers need to sleep at night.

A well-architected program moves asset disposition from a reactive, chaotic task to a proactive, controlled process. It ensures every piece of equipment follows a compliant path from de-installation to its final certified recycling or destruction.

Turning Liabilities into Sustainable Assets

Beyond avoiding risk, a structured program unlocks some serious financial and operational wins. Instead of paying to haul bulky equipment to a landfill, you can recover valuable raw materials through recycling. Better yet, functional assets that still have some life in them can often be resold, generating revenue that helps pay for the program itself.

This approach is a natural fit for corporate social responsibility (CSR) goals and shows a real commitment to environmental stewardship. For a deeper look into this, check out our guide on creating sustainable laboratory practices. Integrating a recycling program is a powerful way to build a broader sustainability strategy that stakeholders, employees, and the community will notice.

The economic side of this is huge. North America's medical waste management market is valued at USD 6.7 billion and is expected to more than double to USD 13.6 billion by 2035. This explosive growth is fueled by tougher regulations and the sheer volume of medical products, highlighting just how crucial recycling has become.

Building Your Asset Inventory and Program Scope

Before a single piece of equipment leaves your facility, you need a crystal-clear picture of what you have. I've seen countless recycling programs stumble right out of the gate because they skipped this step. A successful program is built on a rock-solid, meticulously detailed inventory. This isn't just about counting boxes; it's about defining the scope of your entire project and establishing an unbreakable chain of custody from day one.

You have to get your boots on the ground for this. The process starts with a physical walkthrough of every storage room, lab, and data closet. Your mission is to identify every single surplus, outdated, or non-functional piece of equipment. Think broad. This covers everything from the big clinical devices and complex lab instruments to the massive web of IT assets that keep your operations running.

Defining Your Program's Coverage

It’s a classic mistake to focus only on the big-ticket items like MRI machines or server racks. A truly effective program is granular. For a hospital in Georgia, that means looking past the patient monitors and including the infusion pumps, EKG machines, and even the stacks of retired hospital beds collecting dust in a warehouse.

The same goes for a lab. The inventory can't stop at centrifuges and fume hoods; you have to account for all the smaller instruments that pile up over years. IT e-waste is another area where details matter—it’s not just servers and PCs, but every monitor, printer, and piece of networking gear. To get a real sense of just how wide the net should be, it helps to review a comprehensive list of accepted lab and medical equipment.

Conducting the Equipment Audit and Classification

With the scope defined, the real hands-on work begins: the physical audit. This means locating and documenting every asset destined for retirement. As you build out your inventory spreadsheet, the next crucial move is to classify each item by its condition. This simple tag is what dictates its path forward.

- Functional: This is equipment that still works perfectly fine but is no longer needed. These assets often have resale value, which can help generate revenue to offset the costs of your program.

- Repairable: These are items that aren't working right now but could be brought back to life without breaking the bank. They're often great candidates for donation or refurbishment.

- End-of-Life: This is the gear that's broken beyond repair, completely obsolete, or—critically—contains sensitive data that must be physically destroyed. These assets are ticketed for secure recycling and materials recovery.

This classification system immediately turns a simple list into a powerful strategic tool for managing your retired assets.

An equipment audit is far more than a checklist. It's the foundational data that informs every single decision that follows, from logistics and data security protocols to potential cost recovery.

Establishing an Ironclad Asset Tagging System

Once your inventory is classified, the final foundational step is putting a robust asset tagging system in place. Every single item slated for removal needs its own unique identifier. That tag must link back to your master inventory sheet, which should hold all the key details: serial number, make, model, original location, and its condition classification.

This system becomes your best friend for ensuring compliance and simplifying documentation down the road. When your disposal vendor shows up for a facility cleanout or lab decommission, they'll scan each tag, confirming every asset is accounted for. This process creates a verifiable, unbroken record that tracks each piece of equipment from your facility all the way to its final disposition—whether that's resale, recycling, or certified destruction.

This kind of meticulous planning is non-negotiable in a field that's growing fast. The global medical waste management market, which includes programs just like this, has swelled to USD 39.8 billion. That number is a direct result of the massive increase in waste from healthcare expansions, and it highlights just how urgent the need for compliant, sustainable disposal solutions has become.

Mastering Data Security and Regulatory Compliance

This is where the rubber really meets the road. A recycling program can look great on paper, but if you don’t have a rock-solid handle on data security and environmental regulations, you’re exposing your facility to massive risks. We’re talking about more than just getting rid of old machines; it’s about protecting your patients, your reputation, and your bottom line.

Think about how many modern medical and lab devices have some form of data storage—patient monitors, imaging machines, sequencers, even the servers in the back room. They all contain hard drives or flash memory. Often, that storage is loaded with Protected Health Information (PHI), which turns every single device into a potential HIPAA landmine. A data breach isn't a simple IT headache; it's a catastrophic compliance failure that brings severe fines and erodes public trust for years.

Getting HIPAA and Data Sanitization Right

When it comes to HIPAA, the directive is crystal clear: PHI must be rendered unreadable, undecipherable, and non-reconstructible. This isn’t a suggestion—it’s a non-negotiable requirement for any covered entity, from a major hospital network down to a local Atlanta-area research clinic. Your recycling program has to include an explicit, documented process for sanitizing every data-bearing device that leaves your control.

The biggest mistake I see facilities make is assuming that deleting files or reformatting a hard drive is enough. It isn't. Sophisticated recovery tools can pull that data right back, leaving you completely exposed. True compliance demands certified, verifiable data destruction.

This forces a critical decision: how, exactly, are you going to destroy that data? For a deeper dive into the specifics, it’s worth reviewing the requirements for HIPAA compliant data destruction services to understand the full scope of your responsibilities.

Data Sanitization Methods Comparison

Deciding how to sanitize your assets is a pivotal part of any compliant program. The choice between wiping a drive and physically destroying it often comes down to the asset's condition and its potential for reuse. This table breaks down the two most common methods.

| Method | Description | Best For | Compliance Level |

|---|---|---|---|

| DoD 5220.22-M Wipe | A software-based method that overwrites data with patterns of ones and zeros in 3 separate passes, making the original information irrecoverable. | Functional hard drives in computers, servers, and medical devices that may be refurbished or resold. | High. Meets NIST 800-88 Clear standards and is widely accepted for HIPAA compliance when performed by a certified vendor. |

| Physical Destruction | The process of physically shredding, crushing, or disintegrating hard drives and other storage media into small, unusable pieces. | End-of-life, non-functional, or obsolete devices where data wiping is not possible or desired. | Absolute. Provides the highest level of security as the media is completely destroyed, meeting NIST 800-88 Destroy standards. |

For example, a hospital retiring a fleet of perfectly functional laptops would likely opt for a 3-pass wipe. This secures the data while preserving the hardware's value for remarketing. On the other hand, a diagnostic machine with a failed, integrated solid-state drive would be a prime candidate for physical destruction.

Beyond HIPAA: Environmental Compliance with RCRA

While data security is paramount, it’s not your only regulatory hurdle. A lot of electronics, including medical and lab equipment, fall under the Resource Conservation and Recovery Act (RCRA). This is the federal law that governs how solid and hazardous waste gets handled.

Things like old CRT monitors contain lead, and circuit boards are often laced with mercury, cadmium, and other toxic materials. Just tossing these items in a dumpster can lead to significant environmental fines. A compliant recycling program ensures these hazardous components are properly managed, separated, and processed according to both federal and state laws, including those specific to Georgia.

The growing need for these specialized programs is obvious when you look at the market. While the broader medical waste management sector is projected to hit USD 24.32 billion, niche markets like regulatory-compliant medical device plastics recycling are already valued at USD 106.0 million. This shows a clear industry shift toward specialized, environmentally sound disposal that addresses specific regulations.

Ultimately, mastering compliance means building a program that tackles both data and environmental risks head-on. It requires asking tough questions of your recycling partner and demanding documented proof of compliance every step of the way.

How to Vet and Select the Right Recycling Partner

Choosing the right partner for your medical equipment recycling program is arguably the single most important decision you'll make in this entire process. A truly qualified vendor is much more than just a pickup service—they are your front-line defense against costly compliance violations and devastating data breaches.

Whether you need a local specialist for a lab in the Atlanta metro or a provider with a national footprint for a multi-state hospital system, the vetting process has to be rigorous. It needs to go far beyond simply comparing price quotes.

Your selection will directly impact your program's success, security, and sustainability. The wrong partner can expose your organization to significant liability, while the right one provides an ironclad, documented process that gives you complete peace of mind. This means looking for a partner who can provide detailed, verifiable proof of their capabilities and compliance.

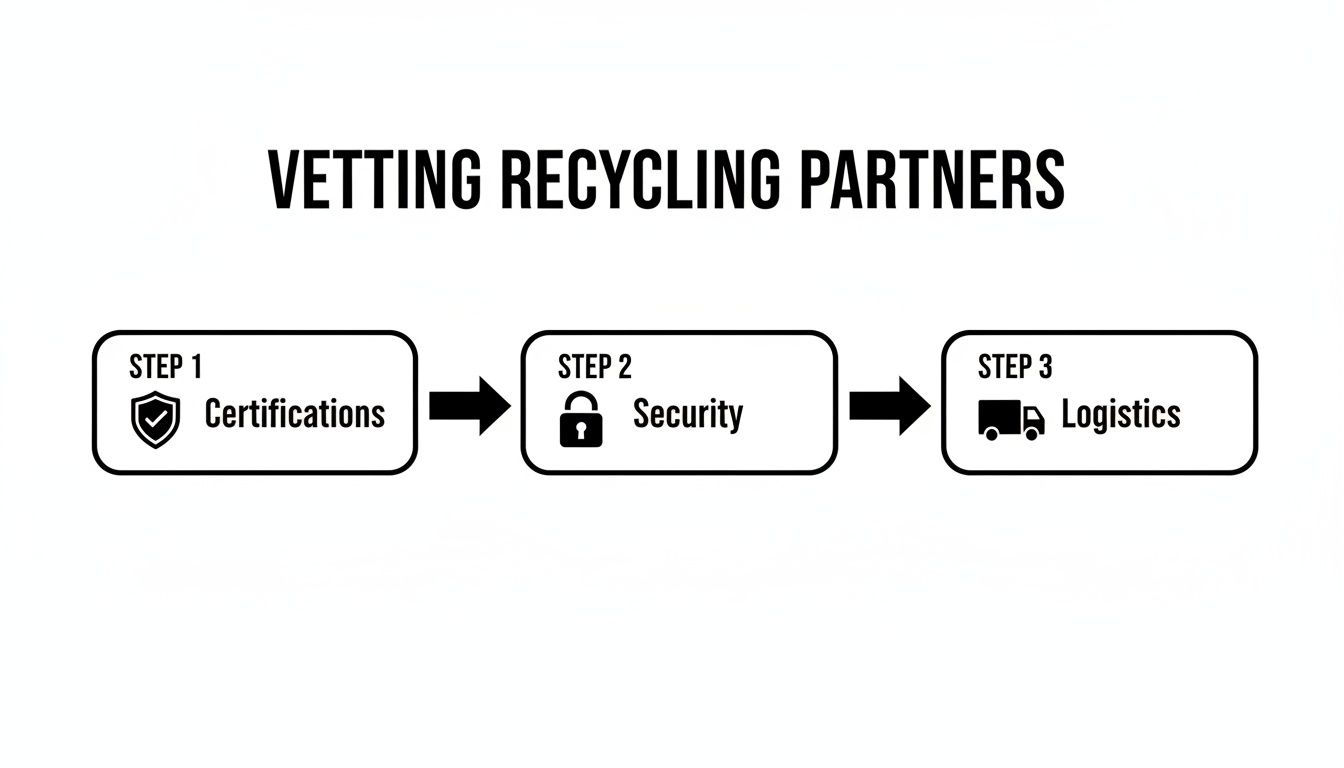

Non-Negotiable Certifications and Insurance

Before you even get into logistics or pricing, your evaluation must start with two foundational pillars: certifications and insurance. These are the credentials that prove a vendor operates to the highest industry standards for environmental stewardship and data security.

You need to look for key electronics recycling certifications. The two most reputable standards in the industry are:

- R2 (Responsible Recycling): This certification ensures the vendor follows best practices for environmental protection, worker health and safety, and data security throughout the entire recycling chain.

- e-Stewards: This is another globally recognized standard, known for its extremely strict requirements that prohibit the export of hazardous electronic waste to developing countries.

A vendor holding one or both of these certifications has already been through intensive third-party audits. It's a clear signal they are committed to responsible processing.

Never just take a vendor's word for it. Always ask for a copy of their current certification documents. An uncertified partner introduces an unacceptable level of risk to your medical equipment recycling program.

Equally critical is their insurance coverage. Request a certificate of insurance and verify they carry robust policies for general liability, pollution liability, and cyber liability (data breach insurance). This coverage is your safety net, protecting your organization in the unlikely event of an accident, environmental incident, or data security failure during transport or processing.

Probing Their Data Security and Logistics Capabilities

Once you've confirmed certifications and insurance, it's time to drill down into their operational processes. A vendor's ability to securely handle your assets from the moment they leave your facility is paramount. This is where you separate the real experts from the amateurs.

Your list of questions should be direct and specific. Don't settle for vague answers; demand clear, documented procedures for every single step.

- What is your process for on-site asset verification? They should be able to describe a clear system for matching their inventory count against your asset-tagged list before anything gets moved.

- Do you own and operate your own truck fleet? A company-owned fleet with trained, background-checked employees provides a much more secure chain of custody than using third-party freight companies.

- How do you handle on-site de-installation and packing? For heavy or sensitive machinery, their team must have the expertise to safely de-install, palletize, and shrink-wrap equipment to prevent damage and ensure secure transit.

- What are your specific data destruction methods? They must be able to clearly articulate their processes for both DoD 5220.22-M 3-pass data wiping and physical shredding, and explain when each method is used.

- What documentation will I receive? A reputable partner will provide a serialized Certificate of Destruction and Recycling that details every single asset processed, creating a crucial audit trail for your records.

These questions reveal a vendor's true capabilities. For facilities planning complex projects like lab decommissions, it's essential to find a partner who can manage the entire workflow. Exploring the details of full-service scientific equipment disposal services can provide a benchmark for what a top-tier provider should offer, from initial logistics planning to final documentation. Choosing the right partner transforms a complex obligation into a manageable, secure, and compliant operation.

Nailing the Logistics and Documentation

You’ve picked your vendor, and now the real work begins. This is where your plan moves from paper to the loading dock. The operational side of a medical equipment recycling program is all about flawless execution—getting the logistics and documentation right to sidestep any expensive missteps. A smooth process means coordinating everything from the initial pickup to the final compliance report.

The complexity here can swing wildly depending on what you're getting rid of. Imagine the difference between a hospital retiring a single, massive MRI machine versus a university lab clearing out dozens of old servers, centrifuges, and incubators.

One job needs specialized heavy rigging and transport; the other is all about meticulous asset tracking and careful packing. A truly capable partner will have a clear, battle-tested process for both.

Coordinating On-Site De-Installation and Transport

The first step you'll see is the on-site work. For heavy machinery, this isn't just a simple pickup. It's a carefully planned de-installation. Your vendor’s team shouldn't just show up with a truck; they need the right tools and know-how to safely disconnect, palletize, and shrink-wrap bulky, sensitive equipment.

This is what protects the asset during transit and prevents damage to your facility. It's a critical service that separates the real specialists from a generic hauling company.

Once everything is prepped, the focus shifts to secure transport. You absolutely have to insist on a partner that runs its own fleet of trucks with background-checked drivers. This creates an unbroken, secure chain of custody from your facility to theirs, a must-have for both HIPAA compliance and general liability.

The infographic below really drives home what to look for in a partner who can deliver on these crucial logistical and security promises.

It highlights that secure logistics are just as vital as certifications and data security when you’re making your choice.

Why Your Paper Trail is Non-Negotiable

In the world of compliance, if you can't prove it, it never happened. Meticulous documentation is your ultimate defense, your shield during an audit, and your guarantee that every single asset was handled by the book. Two documents are absolutely essential.

First is the Asset Disposition Log. Think of this as your master record, which should be built directly from your initial inventory list. As your vendor's team removes the equipment, they need to be scanning each asset tag and verifying it against your list. This creates a trail that follows every item from its original spot in your facility to its final destination—be it resale, recycling, or total destruction.

Without a detailed and verified disposition log, you're flying blind with a massive compliance gap. It's the foundational document that connects your inventory to the final certificates you’ll receive.

The second critical piece of paper is the Certificate of Destruction or Recycling. This isn't just a receipt; it's the formal, legally binding report from your vendor after the job is done. You need to keep this in your records.

A proper certificate will always include specific, auditable details:

- A Unique Serial Number for tracking.

- Your Facility's Information to clearly identify your organization.

- A Detailed List of Assets, including serial numbers, makes, and models.

- The Method of Disposition (recycled, resold, or destroyed).

- The Date of Service to pinpoint when processing occurred.

- A Statement of Compliance, formally declaring that all work met HIPAA, RCRA, and other relevant standards.

This certificate is your definitive proof that the program was executed correctly. It closes the loop on the chain of custody and gives you the peace of mind that comes from a well-managed, compliant process. To see how these steps all fit together in a real-world scenario, checking out a detailed overview of how the equipment disposal process works can offer some valuable clarity on everything from the first call to the final paperwork.

Common Questions About Medical Equipment Recycling

When it comes to setting up a medical equipment recycling program, a lot of questions pop up. It doesn’t matter if you’re a hospital administrator in Atlanta or a lab manager for a nationwide university system planning a consolidation—you need clear, straightforward answers. Let’s get into some of the most common things we’re asked by organizations just like yours.

What Kinds of Equipment Can Actually Be Recycled?

This is usually the first question people ask, and the answer is almost always bigger than they expect. A truly professional medical equipment recycling program can handle a huge range of assets, not just the big, obvious diagnostic machines.

Your vendor's list of accepted items should be clear, long, and cover every type of surplus asset you might have. This is key to making sure everything from a small benchtop instrument to a massive imaging system gets managed under one roof, with one consistent process.

We’re talking about:

- Clinical Equipment: Think infusion pumps, patient monitors, EKG machines, and even surgical tools.

- Laboratory Instruments: Centrifuges, incubators, fume hoods, microscopes, and all those small pipettes.

- Associated IT & E-waste: Don’t forget the computers, servers, monitors, and networking gear that keep your facility running.

How Do You Guarantee Patient Data Is Protected?

Protecting Patient Health Information (PHI) is the single most important job here. It's completely non-negotiable. As soon as a medical device has a hard drive or any kind of data storage, it's covered by HIPAA, and that data is your responsibility until it’s been certifiably destroyed.

Just hitting 'delete' on a file does absolutely nothing. A reputable partner has to use strict, auditable, and HIPAA-compliant data destruction methods to make sure that information is gone for good and can never be recovered.

For any device holding data, there are really only two ways to do this right. The first is data sanitization, like a DoD 5220.22-M 3-pass wipe, which completely overwrites the drive. This erases the data but keeps the hardware intact for potential reuse. The second is physical destruction, which means shredding the hard drive into tiny pieces.

Either way, you must receive a serialized Certificate of Destruction afterward. That’s your proof for any compliance audit.

Isn’t Recycling Just More Expensive Than Throwing It Out?

If you're only looking at recycling as a line-item expense, you’re missing the forest for the trees. Yes, there are costs for secure transport, certified data destruction, and responsible processing. But these aren't just costs—they're an investment in protecting your organization from massive risk.

Getting caught for improper disposal can lead to jaw-dropping fines for HIPAA or environmental violations. That doesn't even touch on the reputational nightmare that comes with a data breach. The cost of a compliant recycling program is a tiny fraction of the financial and legal disaster from one mistake.

On top of that, a smart program can actually bring money back to you. A lot of functional equipment still has real resale value. A good partner can spot these assets, handle the remarketing, and share a portion of the proceeds with you. This can easily offset—or even completely cover—the program's costs, turning a liability into a documented asset.

Should I Look for a Local or Nationwide Partner?

We get this question a lot: should we find someone local or a company with a bigger footprint? The real answer comes down to your needs. A hospital system based entirely in Atlanta might want a local partner who knows Georgia's state regulations inside and out and can be on-site quickly.

But a national research company with labs scattered across the country needs a partner with a nationwide logistics network. That's the only way to get consistent service and compliance at every single location.

The trick is to find a vendor that can service your specific geographic footprint—whether that's a local medical equipment recycling program or a nationwide one—while delivering the same high standards for certifications, data security, and documentation everywhere they go.

Ready to implement a secure, compliant, and cost-effective recycling program for your facility? Scientific Equipment Disposal provides specialized, sustainable solutions for hospitals, labs, and universities throughout the Atlanta metro area and nationwide. We simplify the entire process, from on-site de-installation and secure transport to certified data destruction and responsible recycling. Learn how we can help you manage your surplus assets with confidence at https://www.scientificequipmentdisposal.com.